Our Capabilities

- Cam operated screw machining

- CNC turning

- CNC milling

- CNC multi axis screw machining

- Laser marking

- Reverse engineering and design assistance using Solid Works

- Proto-types

- Mechanical assembly

- Value added processing

|

|

|

Heather Screw Products Co., Inc. was founded on screw machine technology. We built our company around this equipment. The years of producing high volume quality screw machine parts taught us how to be efficient. That kind of work experience is also found in our CNC machining resulting in cost savings for our customers.

|

|

| Partial view of CNC turning depatrmet. |

|

|

CNC turning was a natural progression from screw machines. We have several turning centers equipped with bar feeds capable of feeding 2 inch diameter bar 12 foot long. We feel that running full length bars maximizes efficiency and minimizes bar-end scrap associated with short bar feeders. In addition to bar feeding on turning centers we also have the capability to chuck larger parts up to 17 inch in diameter. See our turned parts in the photo gallery.

|

Some turned parts require extensive CNC mill work to complete and by adding CNC milling allowed us to offer our customers a "one stop shop" for there machining needs. In addition to milling on turned parts we also manufacture a large volume of parts that are exclusively CNC milled.

Our CNC milling capabilities include up to 40 X 20 X 20 travel and 4 axis machining. For high production milling we have machines that rapid at 2g acceleration and tool changes at 1.8 seconds. At Heather Screw Products Co. we are much more that turned parts company. We offer a complete solution for all of your machining needs.See milled parts in the photo gallery.

| |

|

|

| CNC multi axis screw machining |

|

| 7 Axis CNC screw machine |

|

| Our CNC multi axis screw machine offers some of the most advanced technology available. This 7 axis machine has the ability to turn both front and back sides of a part as well as mill, cross drill and tap in a linear and axial direction. This gives us the ability to produce parts complete in one operation eliminating secondary handling. This machine is also equipped with an LNS 332 magazine bar loader which allows us to run lights our for maximum production requirements. See parts produced on multi axis CNC screw machine in the Photo Gallery.

|

|

|

|

| Electrox 25 watt fiber laser |

|

| Laser marking is another value added service we offer. With our 25 watt fiber laser we have the ability to mark on aluminum, steel, stainless steel, carbide and a variety of other materials. With the ability to mark as small as .002 of an inch fiber laser produces one of the finest marks available from any laser. Laser marking isn't only for parts we produce. If we make them or you just need them marked we are happy to help. Contact us for more information. See laser marked parts in the photo gallery.

|

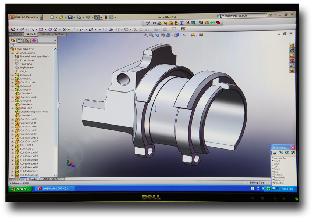

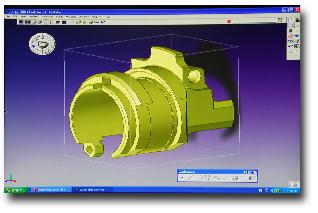

| Reverse engineering, Rapid Prototyping, CAM programing and finished part |

|

| Reverse engineering using Solid Works CAD software |

|

|

|

| Rapid Prototype |

|

|

|

| CAM programing using Virtual Gibbs software |

|

|

|

| Finished Part |

|

|

If you require design assistance or just machining we can help. This part was completely reverse engineered and drawn in Solid Works. The solid model drawing was output to a 3D rapid prototyping machine and a solid plastic part was made to verify the design. The same file can be imported into our Virtual Gibbs CAM programming system and the machining process is developed. The finished machined part is shown in the lower right picture above.

|

Quality Control is an important part of any machine shop. Heather Screw Products is no exception. We have a complete quality control department consisting of optical comparators, micrometers, height gages, bench centers, thread ring and plug gages, surface profolometers and various other gages to verify all critical dimensions are maintained to our customers specifications.

|

|